Weight Optimization

- DEP is a leading provider of innovative, value-creating steel solutions, with introduction of several new and upgraded material solutions, coupled with an efficient manufacturing process engineered to enable the automotive industry to achieve greater cost efficiency, higher performance and improved sustainability in vehicle components.

- DEP’s experience working with high strength materials coupled with our advance parametric tools in the automotive industry enables superior light weight solutions.

- DEP’s ability to lightweight, along with performance compliance has been a great enabler for our customers.

- DEP has proven on multiple occasions while working with steel companies that given a right combination of steel grade with optimized shape, gage and other geometrical parameters, steel designs can have a cost and weight efficiency as compared to other alternate materials like aluminum, magnesium or composites.

- Our engagements with various steel companies and expertise of handling the material grades based on manufacturing knowledge delivers a superior edge to all customers.

DEP'S UNIQUE 3G+ APPROACH

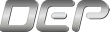

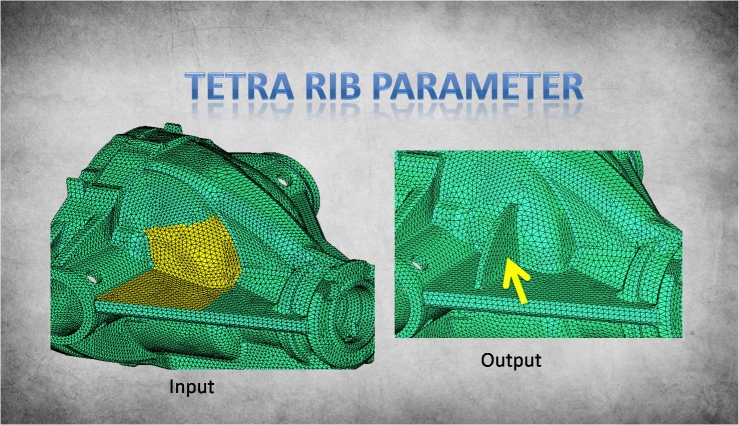

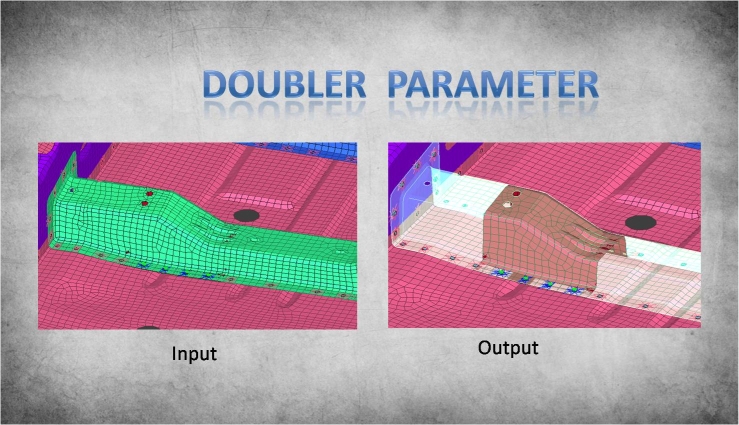

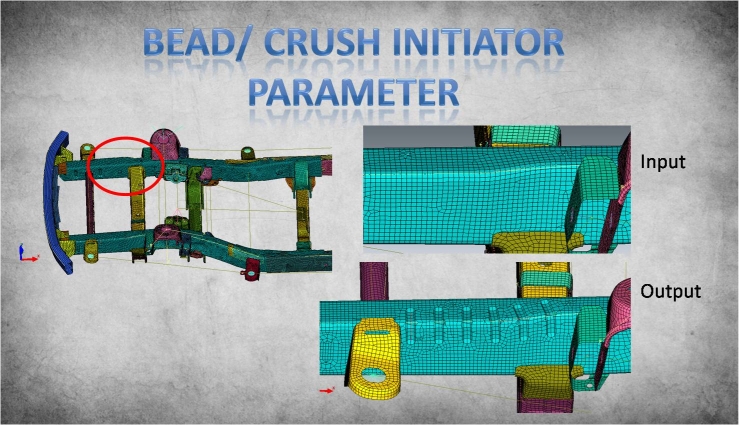

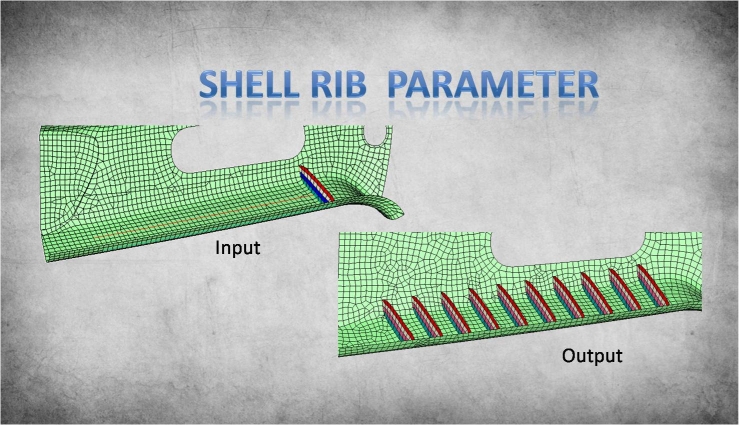

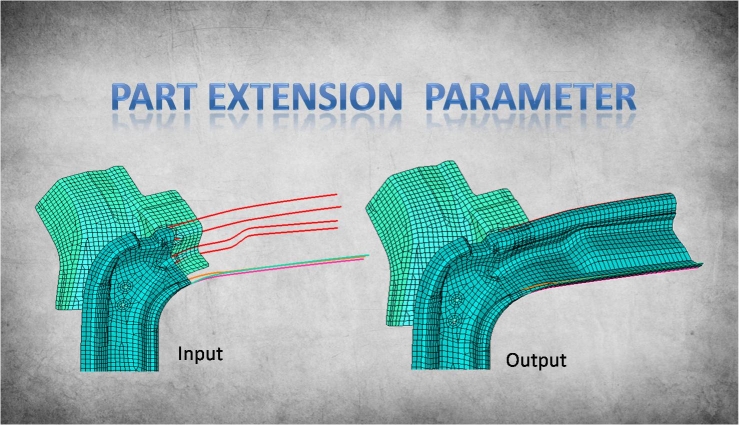

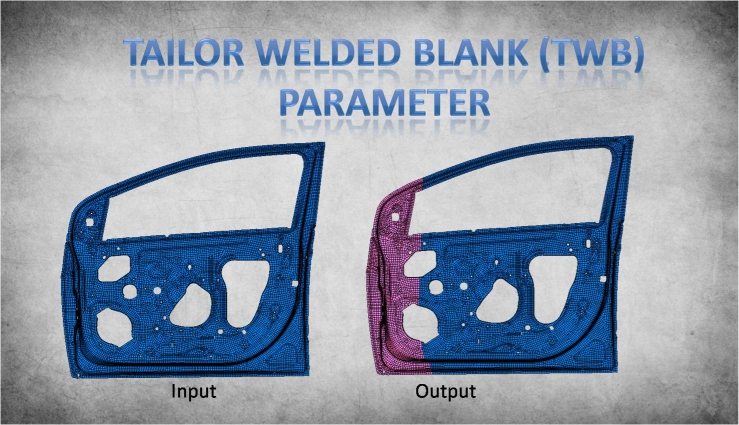

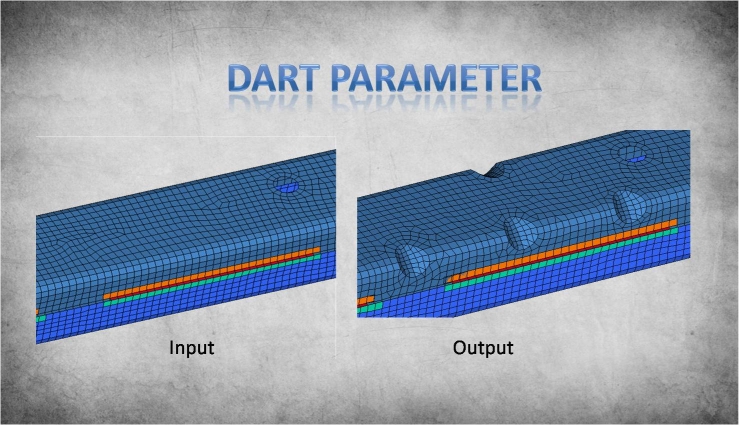

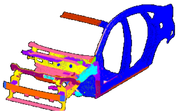

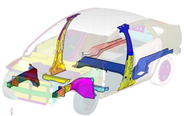

DEP MeshWorks enables MDO weight reduction studies using a 3G+ approach whereby Gage, Grade (material), Geometry and a ‘plus’ suite of design enablers such as welds, adhesives, beads, darts, TWB/TRB, bulkheads, doublers, holes/slots, part-extension/contraction can be used as parameters to extract the last ounce of material from the BIW while meeting all performance targets.

SUCCESS STORIES

A large OEM’s current production mid-size sedan was significantly lightweighted and weld count reduced by DEP through its MDO process. The OEM’s powertrain group has benefitted from DEP’s morphing based multi-disciplinary weight optimization process, and transformed its entire virtual analysis procedures embedding DEP’s successes on major engine and transmission programs.

DEP’s weight optimized ALL STEEL BIW for a very large OEM at 172 Kg is considered an industry first for lightest steel body meeting all crash, NVH & durability targets. The above design has been set as an internal benchmark cum target at the OEM and has been multi-discipline optimized (MDO) by DEP as per OEM load cases, modeling practices and design for manufacturing standards.

DEP performed full vehicle parameterization and MDO for an SUV, resulting in a mass saving of 11 kgs, with minimal packaging and tooling changes and without any degradation in performance. DEP MeshWorks driven MDO approach has been successfully extended beyond full vehicle to various other vehicle sub systems as well. READ DETAILED CASE STUDY…

For one of the world’s largest composite manufacturer, DEP was able to reduce the mass by 28 percent, with an improvement in performance, and was able to convert Aluminium bulkheads into a composite glass fiber reinforced bulkhead, to gather same level of stiffness. READ DETAILED CASE STUDY…